FORTEM Sets Record AAC Production in Iernut, Announces Expansion and Development Plans

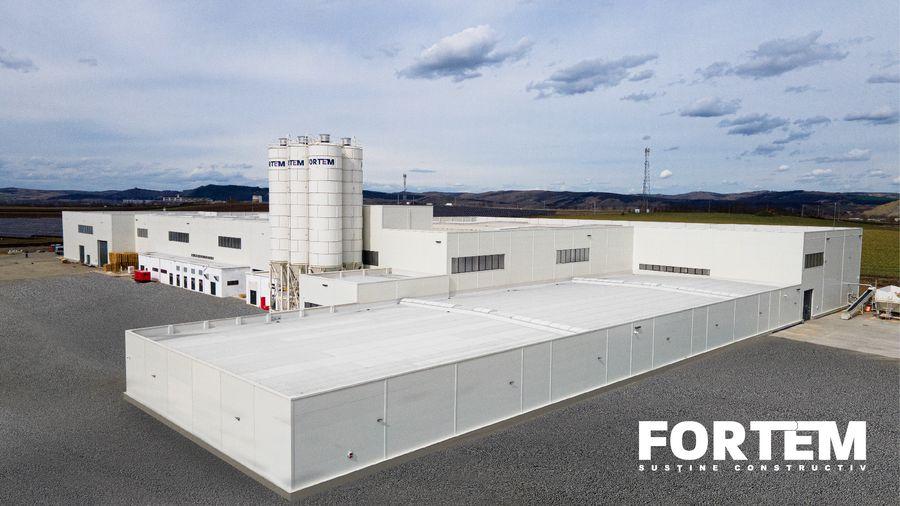

FORTEM, through its parent company DVI Production, inaugurated a new autoclaved aerated concrete (AAC) manufacturing plant in Iernut, Mureș County, in May 2025, following an investment of approximately EUR 40 million. Strategically located near the Transylvania Motorway, the facility spans more than 10,000 square meters and has a production capacity of 2,000 cubic meters of AAC per day.

With this investment, FORTEM aims to position itself as a benchmark in the energy-efficient masonry materials segment, serving both the domestic market and export destinations, while maintaining a strong commitment to reducing carbon emissions and improving construction quality.

Looking ahead to the 2025–2030 period, the company plans to expand its portfolio beyond AAC blocks to include AAC panels—an innovative and versatile solution designed to meet the growing demand for energy efficiency and sustainability in construction. These panels are particularly suited for large-scale projects, offering significantly shorter construction times and enhanced thermal performance.

FORTEM will also continue to invest in innovation and research, aligning its development strategy with global trends in the construction industry and addressing key challenges related to sustainability, energy efficiency, and environmentally friendly materials. In the coming years, the company intends to launch additional products to complement its existing portfolio and deliver integrated, high-performance solutions for construction professionals.

According to Cristina Piteșteanu, Marketing Manager at DVI Production – FORTEM, the rapid expansion of the NZEB (Nearly Zero-Energy Buildings) market in Romania is expected to generate substantial growth opportunities. This trend is driven by stricter thermal performance standards, lower emission thresholds, and increasingly demanding sustainability requirements for masonry materials.

- How has the Romanian market for energy-efficient / NZEB building products evolved over the past two years, and how do you see this sector developing between 2025 and 2030?

- The NZEB products market has grown both in terms of diversification and individual volumes across segments, driven by funding mechanisms and regulations.

In the AAC segment, stricter requirements for walls are expected, with recommendations that the thermal transmittance coefficient be equal to or lower than U = 0.15 W/m²K. Additionally, standards are expected to place greater emphasis on thermal bridges, airtightness, and integrated systems (including how masonry connects with insulation and installations).

“Conventional” masonry materials will become increasingly difficult to use on their own unless combined with high-performance insulation or superior thermal-efficiency masonry solutions.

AAC masonry with thicknesses of 30+ cm, high-performance vertically perforated bricks (e.g., with mineral wool), or prefabricated solutions such as SIP panels will gain ground. At the same time, masonry materials will need to be integrated into the overall performance of the building: energy calculations will consider exterior walls, thermal bridges, airtightness, and more.

Manufacturers will likely be required to provide detailed performance data for masonry elements: λ (thermal conductivity), U-values for the masonry + insulation system, moisture resistance, durability, etc. Builders and architects will need to design using higher-performance materials and verify system compatibility (masonry + insulation + windows + installations) as a complete package.

Local masonry material manufacturers have a real opportunity if they adapt their products to NZEB requirements – in our case, large-format masonry blocks with low thermal conductivity and, in the future, FORTEM AAC panels, masonry prepared for external insulation, and prefabricated systems.

The market for masonry blocks with integrated insulation or masonry + thermal insulation systems will expand, offering opportunities for Romanian producers and importers positioned in this niche.

The 2026–2027 period is expected to be challenging for the Romanian construction industry; however, as manufacturers, we are taking all necessary steps to remain aligned with beneficiary needs and market conditions.

In the residential sector, during the first quarter of 2025, the number of building permits increased by 2.8%, while the authorized usable area also rose by 1.4%. The upward trend in permits indicates growing interest in apartment construction in response to market demand, while the modest 4% increase in authorized surface area suggests more compact or more efficiently organized projects.

In the non-residential sector, for the 2026–2027 period, we anticipate a stabilization, supported by Romania’s relatively positive economic outlook, with estimated growth of approximately 1.2% in 2026 and 3.3% in 2027.

- What NZEB and energy-efficient products are included in your portfolio, and which were most in demand in 2025?

- Our entire portfolio has been designed specifically for NZEB buildings and energy efficiency. At present, we operate at partial capacity, adjusting volumes and product dimensions according to market requirements.

We also plan to expand production to include customized orders, particularly in segments where demand for materials with densities above 500 kg/m³ remains constant.

Thanks to the modern infrastructure and advanced technology implemented in our factory, we are close to reaching the full capacity of 2,000 m³/day, further strengthening our market position and commitment to quality and innovation. Densities above 500 kg/m³ can be produced on demand.

For NZEB buildings, FORTEM AAC with a dry density of 450 kg/m³ and thermal conductivity of 0.1 W/mK can be used, offering thermal and acoustic insulation with zero CO₂ emissions. FORTEM masonry blocks are energy-efficient and thermally insulating, allowing the construction of a 40 cm thick wall in a single stage.

Together with interior and exterior finishes, the FORTEM wall is the ideal solution for insulating a passive building or one with nearly zero energy consumption.

- What characteristics do the company’s new products have in the context of resilience and adaptation to climate change?

- The new products in the company’s portfolio – FORTEM AAC blocks – are characterized by low thermal conductivity and good acoustic insulation. Moreover, AAC material does not emit CO₂; instead, it absorbs it from the atmosphere.

Buildings constructed with FORTEM AAC, due to their low thermal conductivity and sound insulation, represent a favorable solution against climate change, particularly in the context of major temperature variations, without affecting the health of occupants or users.

Approximately 26% of the population considers AAC blocks to be the main sustainable masonry material, recognizing them as an ecological product.

- What are the major challenges currently present in the NZEB / energy-efficient construction market?

- Among the main barriers and risks to market development are: volatility of subsidies and support programs (e.g., AFM programs); execution capacity and availability of qualified labor (NZEB installers, commissioning specialists, auditors); administrative delays (authorizations, public procurement); limited access to electrical grids for prosumers and storage; lack of consistent regulations; and social and macroeconomic impacts.

- What does the company’s development strategy for 2025–2030 include? Are you planning investments to expand operations?

- We aim to reach a production capacity of 2,000 m³/day. In addition to AAC blocks, we will introduce AAC panels into production – an innovative and versatile solution that meets current requirements for energy efficiency and sustainability in construction. These panels will be ideal for large-scale projects, significantly reducing construction times and improving thermal performance.

In parallel, we continue to invest steadily in innovation and research, considering global construction trends and the need to address sustainability, energy efficiency, and eco-friendly materials. In the coming period, we will explore the development of new products to complement our portfolio and provide complete, efficient solutions for construction clients.

Our development plans also include expanding transport infrastructure by connecting the factory to the nearby railway. The reduced weight of AAC contributes to energy savings in transportation. Being up to five times lighter than concrete and two to three times lighter than clay brick, AAC significantly reduces CO₂ emissions during transport.

- What challenges and opportunities do you foresee in the energy-efficient construction sector in the short and medium term?

- In a context marked by increasingly strict sustainability regulations and a well-informed public seeking healthy, energy-efficient homes, the choice of construction materials has become a strategic design component. Architects and real estate developers alike are challenged to integrate materials that not only meet technical requirements but also add ecological and social value to projects.

For many Romanians, sustainability matters as much as residential comfort – it is no longer a secondary criterion. At the same time, growing trust in “green” materials is evident. Many people choosing to build a home or move into a new building would opt for sustainable materials, even over more conventional options, as long as they deliver energy performance and a reduced environmental footprint.

AAC is already among the top choices for modern, efficient, and sustainable masonry materials. With the opening of our new factory and the launch of FORTEM AAC products, we join those who build responsibly – architects, developers, builders, or families laying the foundation of the future with care.

By using the latest production technologies, FORTEM AAC not only ensures superior strength and durability but also enables fast and precise execution without additional costs. The production process significantly reduces environmental impact through lower resource consumption and reduced carbon emissions.

Investing in advanced technologies represents a firm commitment by DVI Production – FORTEM to a greener, more responsible future, supporting both sustainable industry development and the creation of a safer, more comfortable environment for professionals and end customers alike.

Our products provide excellent thermal insulation thanks to their porous structure, helping reduce heating and cooling costs year-round, increased seismic resistance through optimized production processes, acoustic insulation, resistance to natural phenomena and temperature variations, and fire protection due to the use of non-combustible materials with high fire resistance ratings.

In conclusion, opportunities are substantial; however, NZEB regulations at the national level must be discussed with authorities to establish alignment, ensuring a common language and approach across legislation and standards